What Is Gravimetric Blending? Understanding the Process, Benefits, and Key Applications

In plastic processing, precision isn't just a nice-to-have—it's essential. Whether you're blending virgin material with regrind, adding color masterbatch, or managing complex formulations, the accuracy of your mixing process can make or break your product quality.

That’s where gravimetric blending comes in. Unlike volumetric systems that rely on timing or flow estimates, gravimetric blending uses precise weight measurements to ensure each ingredient is added in the exact proportion needed. In this article, we’ll break down how it works, why it matters, and where it’s used—so you can decide if it’s right for your production.

What Is Gravimetric Blending?

Gravimetric blending is a method of mixing multiple raw materials—such as plastic pellets, regrind, and masterbatch—based on their actual weight. The process involves metering each ingredient individually into a blending chamber using high-precision load cells and dispensing valves.

This weight-based system stands in contrast to volumetric blending, which dispenses materials based on volume or time. While volumetric systems can be simpler and more affordable, they are often less accurate—especially when dealing with materials of different bulk densities.

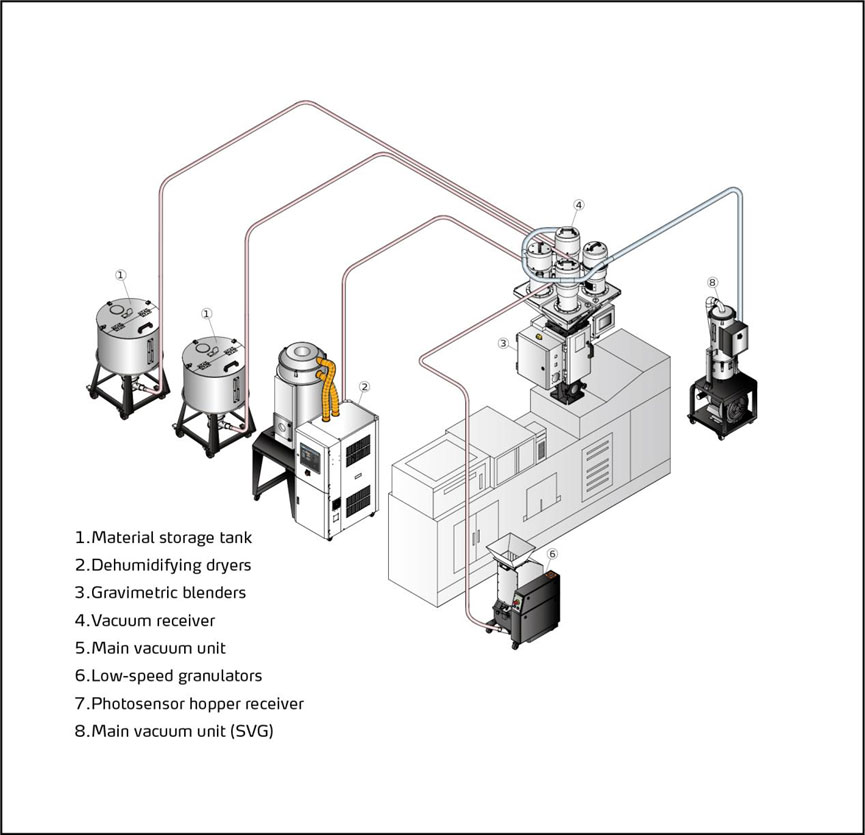

Gravimetric blending systems are often integrated into plastic material handling equipment to form a complete dosing and conveying solution.

(Tripod-mounted gravimetric blender installation for flexible floor setups)

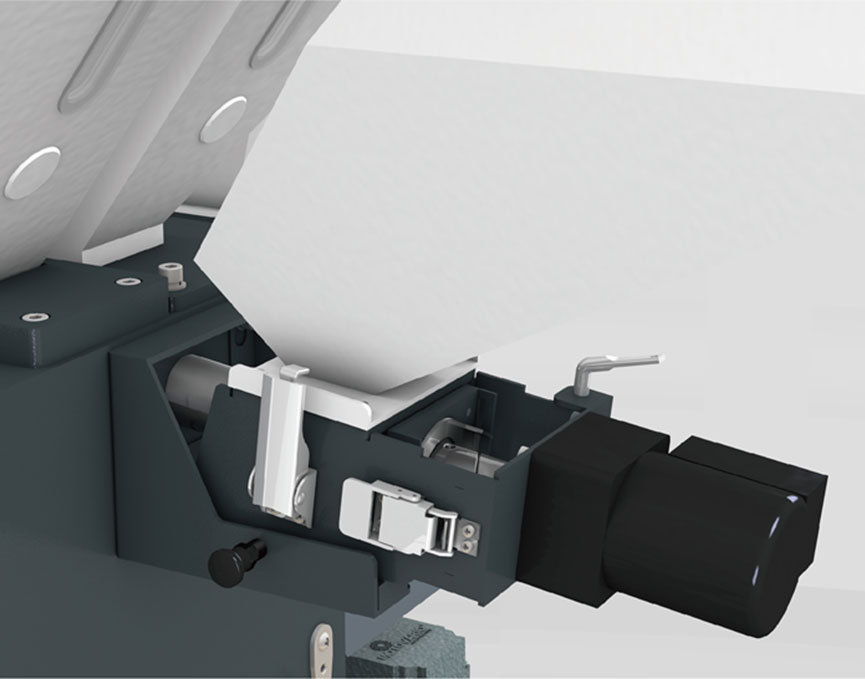

(Machine-mounted blender design for compact integration with processing lines.)

How Gravimetric Blending Works

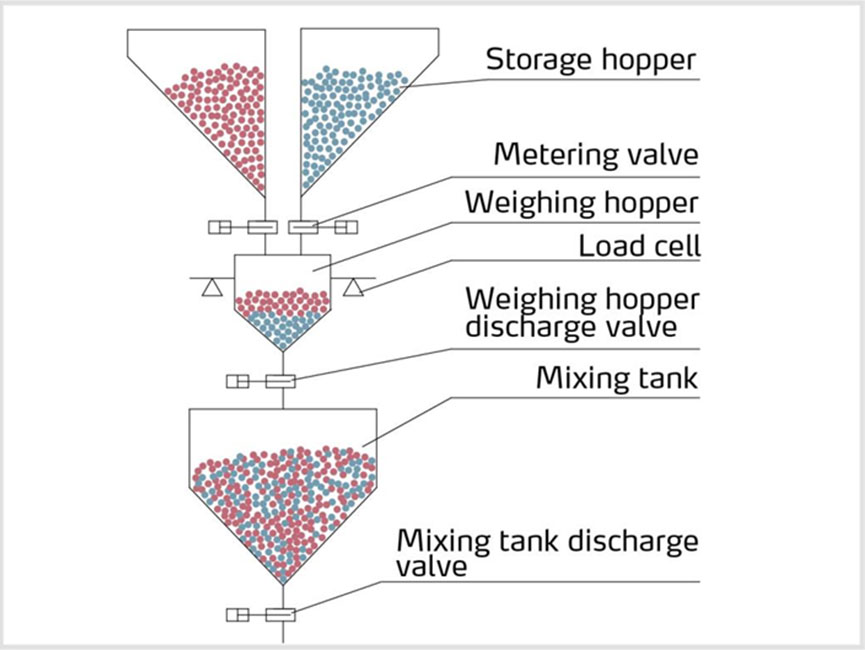

A typical gravimetric blender consists of several core components:

- Material hoppers – store raw materials such as virgin resin, regrind, and color masterbatch

- Load cells – measure each material’s weight before dispensing

- Vertical Metering Valve – control the flow of each ingredient into the mixing chamber

- Mixing chamber – ensures uniform distribution of all ingredients

- Control system – stores multiple recipes and oversees the blending process

(Precision metering screw ensures accurate batch dispensing of multiple ingredients.)

Blending Workflow:

- Materials are stored in dedicated hoppers.

- One material at a time is dispensed into a weighing module.

- Once the correct weight is reached, it is released into the mixing chamber.

- The process repeats for all ingredients.

- The final blend is mixed thoroughly before being discharged to the next stage of production.

(Illustration of gravimetric blending working principle: real-time weighing and dosing.)

Key Benefits of Gravimetric Blending

Gravimetric blending offers several performance and cost-saving advantages:

-

Superior Accuracy

Achieves dosing accuracy as tight as ±0.1%, significantly improving product consistency and reducing rejects. -

Material Savings

By preventing overfeeding, gravimetric systems can reduce raw material consumption, especially in colorant and additive applications. -

Batch Traceability

Integrated controls record every batch’s data—including weights, recipe numbers, and alarms—for quality assurance and regulatory compliance. -

Consistency Across Batches

Gravimetric systems remove variability caused by bulk density shifts or inconsistent material flow, ensuring every batch is identical.

Common Applications in Plastics and Beyond

Gravimetric blending is widely used in:

- Plastic extrusion lines – such as film, pipe, or sheet production

- Injection molding – for color and additive integration

- Regrind blending – to mix recycled and virgin material precisely

- Color masterbatch dosing – where exact pigment ratios are critical

- Other industries – including food, pharmaceuticals, and chemicals that require strict blending control

In plastics recycling operations, gravimetric blending is often paired with downstream equipment such as an industrial plastic granulator and blades for plastic granulators, helping ensure uniform material preparation before reprocessing.

(SGB system in use with injection molding equipment.)

(Integration of SGB with extrusion processing lines.)

(SGB deployment in blown film production for consistent material quality.)

Is Gravimetric Blending Right for Your Process?

Gravimetric blending is ideal for operations that:

- Require precise formulation and repeatable quality

- Use multiple materials with different densities

- Produce high volumes with strict quality control

- Need data logging and traceability

- Aim to reduce raw material waste

For smaller-scale operations or simpler formulations, volumetric blending may still be suitable—but as production complexity increases, gravimetric blending becomes a worthwhile investment.

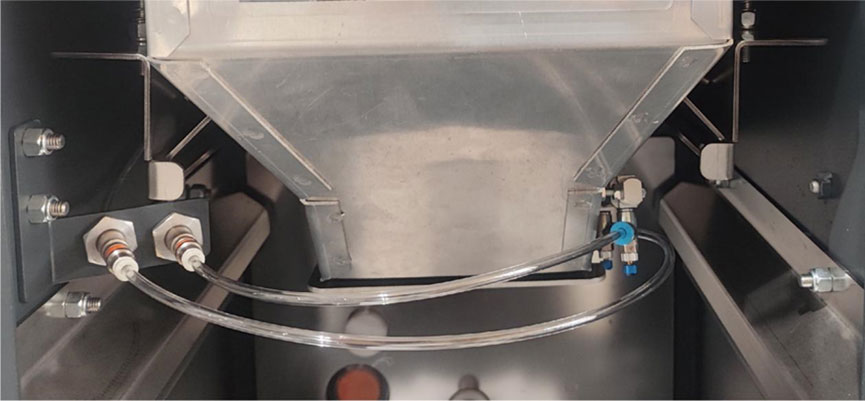

(Quick-connect air fittings allow fast setup and maintenance of pneumatic controls.)

Take the Next Step in Gravimetric Blending

Gravimetric blending is more than just a technology—it's a foundation for smarter, more consistent production. By combining high-precision hardware with intelligent control systems, it empowers manufacturers to meet tighter tolerances, minimize waste, and stay competitive in fast-evolving markets.

Curious how gravimetric blending compares to other approaches? Don’t miss our deep dive into Batch vs. Continuous Blending: Which Method Is Right for You? to see how different systems impact efficiency, consistency, and flexibility.

Learn more about how we bring precision blending to your production floor: Gravimetric Blenders Product Page